Hyundai, LG to build battery cell facilities in Indonesia

Hyundai, LG to build battery cell facilities in Indonesia

Posted July. 30, 2021 07:20,

Updated July. 30, 2021 07:20

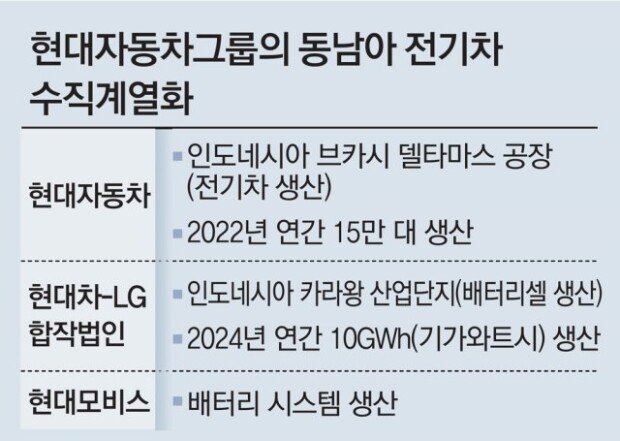

Hyundai Motor Group and LG Energy Solution will mass-produce battery cells that can accommodate 150,000 EVs a year when their joint manufacturing facilities come online in 2024 in Indonesia. Hyundai Motor will complete the last puzzle of vertical integration in the Indonesian car industry where Japan has gained a greater competitive edge while LG will have its fifth fabrication hub in Indonesia following South Korea, the United States, China, and Poland.

The two South Korean businesses on Thursday announced their plan to jointly build battery cell manufacturing factories in Karawang New Industry City, Indonesia. Built on land of 330,000 square meters, the battery cell networks will produce 10GWh a year as per their blueprint.

A joint venture (JV) will be launched by Hyundai and LG in the 3rd quarter of the year. As commencement of construction on the site is scheduled in the 4th quarter, the project will get completed to execute commissioning in the first half of 2023. The two conglomerates agreed to invest 1.1 billion dollars each in the battery cell facility project to earn 50 percent of the JV’s shares each.

What attracts the two South Korean pioneers to Indonesia is that the country ensures easy access to core materials for battery fabrication such as nickel and cheap labor cost. Indonesia is the world’s largest nickel reserves and mines the greatest amounts of the metal in the global market. Given this, the Indonesian government has nurtured EV-related industries. The Hyundai-LG joint manufacturing facilities in Indonesia will receive exemption benefits for corporate tax and tariffs.

The Hyundai-LG battery cell facilities plan to produce high-performance NCMA lithium battery cells with nickel, cobalt, manganese and aluminum added to them.

If the joint venture is established as planned, South Korean cars can find it easy to make inroads into the Indonesian market. A complete vehicle factory system is under construction in the Deltamas Industrial Complex in Bekasi with Hyundai Motor Group at the helm of construction. Hyundai Mobis will take charge of battery system fabrication. When the project is finished within this year, they will be capable of producing an annual output of more than 150,000 units of complete cars including EVs. Around the time the joint factory system with LG Energy Solution gets completed, Hyundai Motor Group will complete an EV supply chain of batteries, auto parts, and complete units.

LG Energy Solution plans to increase battery production capabilities to 155GWh this year, and including two joint factories in cooperation with General Motors, LG’s production capacity will go up to 260GWh by 2023.

will@donga.com · skytree08@donga.com

Headline News

- Joint investigation headquarters asks Yoon to appear at the investigation office

- KDIC colonel: Cable ties and hoods to control NEC staff were prepared

- Results of real estate development diverged by accessibility to Gangnam

- New budget proposal reflecting Trump’s demand rejected

- Son Heung-min scores winning corner kick