We must keep Mullae-dong's collective power

We must keep Mullae-dong's collective power

Posted October. 15, 2024 08:26,

Updated October. 15, 2024 08:26

On Monday, we revisited Yoo Dae-soo, 66, a 'missile sculpting artisan' we first interviewed in 2013. Starting his business in 1986 in Mullae-dong, Yeongdeungpo-gu, Seoul, Yoo hand-crafted outer shells for 8-meter-long practice missiles and supplied them to the military. Eleven years later, he no longer makes missile shells, but he’s still creating mechanical parts that bring life to lumps of metal. “I’m still here because my landlord reduced the rent during the Asian Financial Crisis and hasn’t raised it since,” Mr. Yoo said. “A lot of people have left Mullae-dong.”

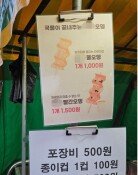

The number of small manufacturers in Mullae-dong has decreased from about 2,600 in the late 1990s to around 1,260 recently. Some have closed due to failure to adapt to larger manufacturing and automation trends or a lack of family succession. The most significant cause, however, is gentrification. The influx of workshops, restaurants, and cafes has increased rents, pushing out the original residents. “Three or four years ago, the monthly rent for a 99-square-meter factory was around 1.5 to 1.8 million won, but now rent for a restaurant in a prime location costs 2.5 million won,” says Choi Yeong-san, head of the Seoul Small Manufacturer Association.

Gentrification is an inevitable trend in Seoul, a dense city. Still, it would be sad to see the Mullae-dong Ironworks Complex, one of Seoul's last remaining clusters of mechanical and metal root industries, disappear after Cheonggyecheon, Euljiro, and Seongsu-dong.

Mullae-dong's greatest strength was its collective power. Thanks to a collaborative ecosystem with a complete value chain of mechanical processes—such as lathing, die-making, casting, welding, and plating—it was possible to produce any prototype within two to three days by visiting just a few neighboring factories. Mullae-dong was known for the saying, 'If you have a blueprint, you can even make a tank in Mullae-dong.' Although it's not the same as it used to be, it still maintains a substantial presence, with an annual production output of 1.2 trillion won.

The problem is land and cost. Small manufacturers in Mullae-dong can't operate in apartment-style factories. When dozens of 30-ton machines start running, precision equipment becomes difficult for precision equipment to handle the vibrations. As a result, they need a complex of single-story buildings. The Korea Institute for Industrial Research and the Community Research Institute estimated that more than 300,000 square meters of land would be needed to transition the factories fully.

If the small manufacturers are scattered, their collective power is lost. A product that costs 1,000 won will cost 2,000 won as small and medium-sized enterprises travel back and forth between local provinces or China to create prototypes. This increased cost will ultimately be passed on to consumers. Mullae-dong's entire movement is not just for small manufacturers.

Headline News

- Joint investigation headquarters asks Yoon to appear at the investigation office

- KDIC colonel: Cable ties and hoods to control NEC staff were prepared

- Results of real estate development diverged by accessibility to Gangnam

- New budget proposal reflecting Trump’s demand rejected

- Son Heung-min scores winning corner kick